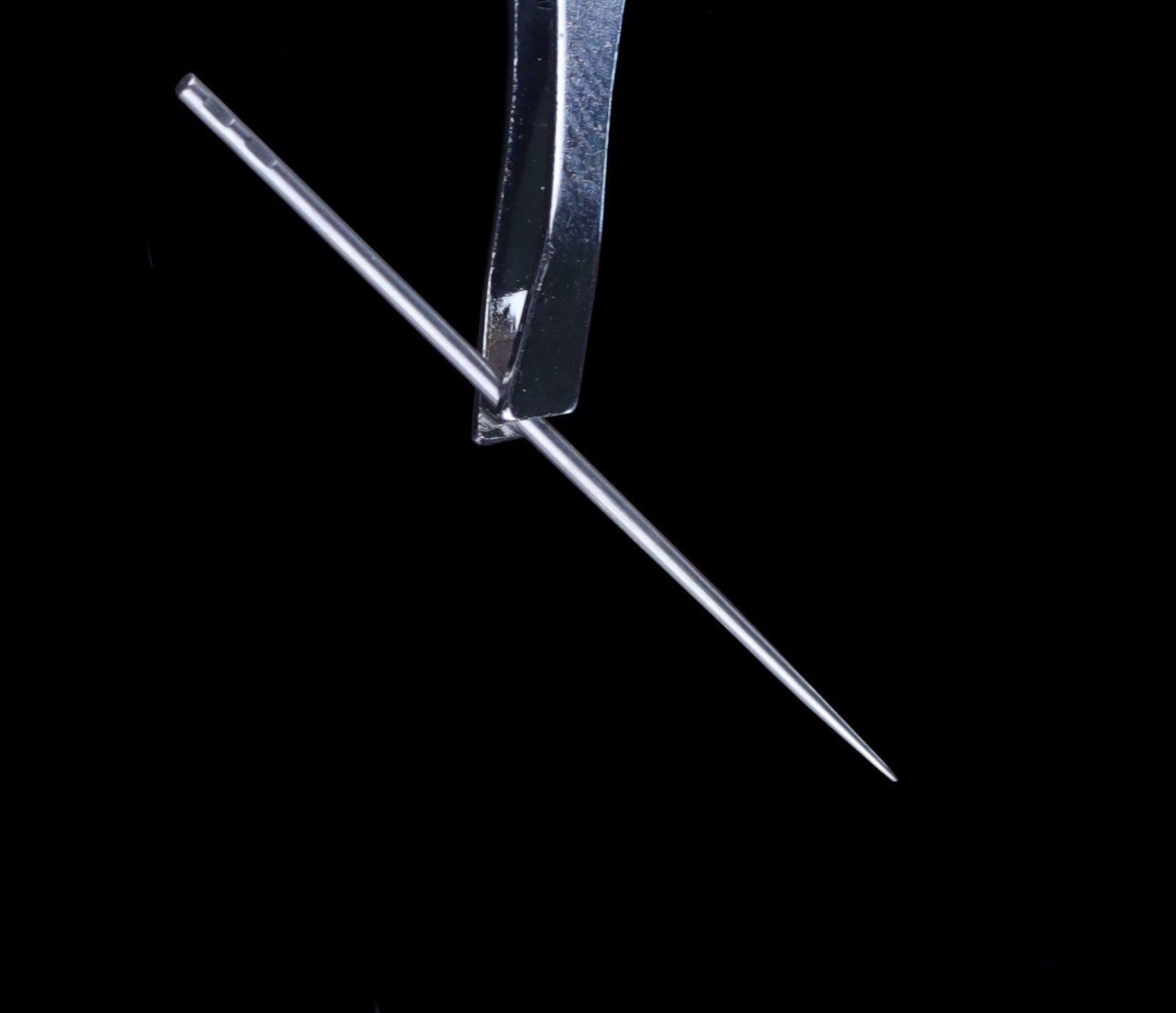

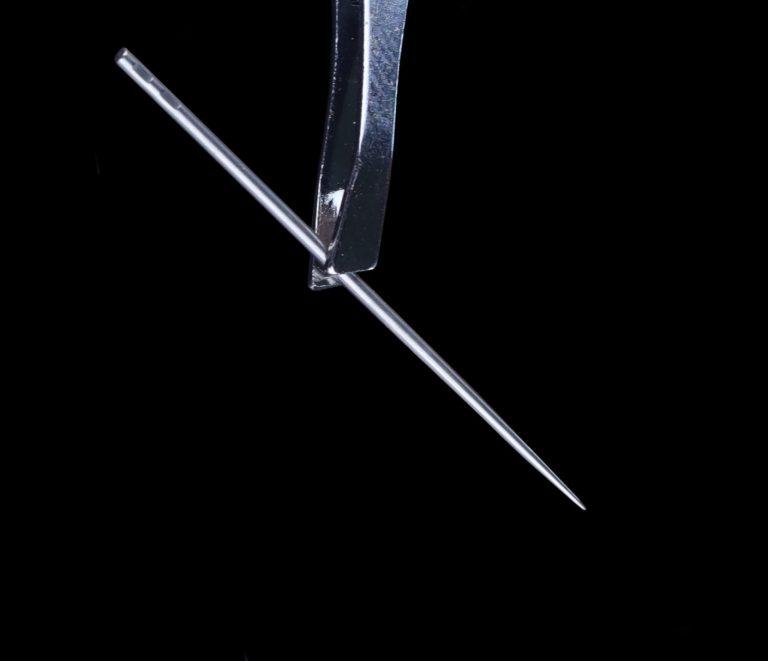

Examples of AXFIL work

Stainless steel dental probe

Function

For use in dental/medical instruments

Technical requirements

Expertise in two key technologies is required to manufacture these parts:

Pointing is used to profile the tip according to an extremely strict set of recommendations in the technical specifications, regarding the shape, spike and surface condition;

Precision stamping is used to form the hook section, ensuring a strong mechanical bond between the tool and the plastic or metal handle.

The aim here is to give the tip an ogival form with a perfectly smooth joint between the cylindrical part (precision of ±0.01 mm in diameter) and the tip, with the fineness of the eye no more than 0.02 mm and a concentricity of ±0.02 mm with respect to the main cylinder. We traditionally manufacture this type of part with wires that have a diameter of 0.25 mm to 3 mm. Our operators have expert knowledge of the 3D settings on these machines to obtain the exact form sought by the customer and for repeatable, large-sized batches on machines designed and developed by us for over a century.

We can make simple conical tips with an angle precision of ±30’, or more complex convex or concave tips. Fine polishing in the final stage produces a perfect surface condition free of any roughness.

The precision of the two forms in the hook section, along with the absence of any burring, is crucial here, considering that this component will be overmoulded in an automated injection press where it must be perfectly and precisely aligned to avoid any additional costs associated with poor quality, production line stoppages or even tool breakage.

Our customers particularly value Axfil’s ability to produce the exact form of the tip they are seeking and the importance it places on finishing and inspecting all of its parts, since this guarantees the smooth and safe operation of their production lines.

Materials

Stainless Steel 1.4310

Sector

Healthcare