Examples of AXFIL work

Function

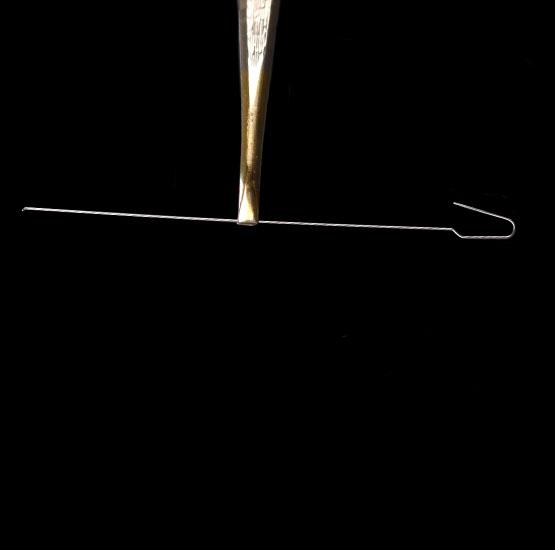

Needle designed for ophthalmic use, inserted in a plastic part

Technical requirements

Laser rounding of end section, precision bending of each end section (dimensional tolerance after bending is ±0.025 mm) with a total length after bending of ±0.10 mm

Ophthalmic surgery requires extremely fine tools that must meet very precise geometric requirements, with no burring or roughness whatsoever.

We make the functional tips of these tools using wire of 0.20 mm to 1.00 mm, with a standard precision of ±0.01 mm at the diameter (which may go as low as a few micrometres). We can either make a fine tip or produce a hemispherical finish using laser fusion and precision bending (±25 µm).

This tip is then inserted in multi-cavity plastic injection moulds at our customers’ premises, employing perfectly controlled and stable geometry to ensure it bonds with the body of the instrument by means of overmoulding.

Our ophthalmic parts are 100% inspected.

Materials

Phynox 2.4711

Sector

Healthcare