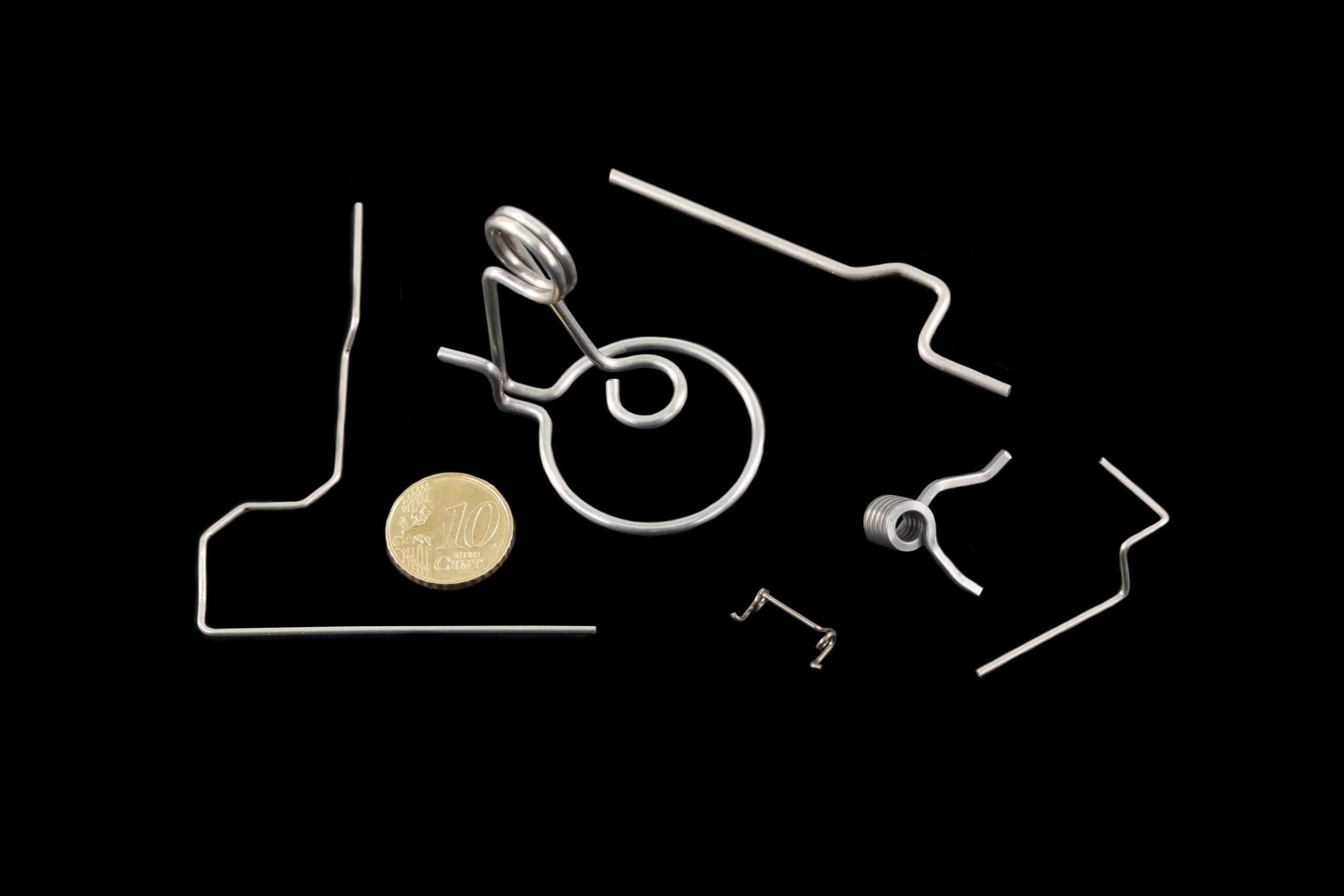

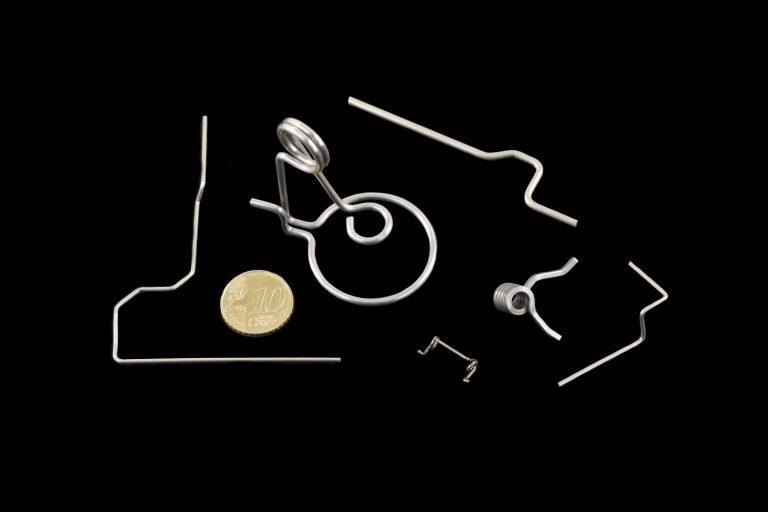

Examples of AXFIL work

Headed pin with tip

Function

Nail for perforating acoustic panels

Technical requirements

Straightening after quenching, ogival precision tip, dimensional repeatability based on form of head.

A cheaper alternative to micro-piercing, these needles can perforate metal sheets to make a multitude of holes simultaneously (up to 18,000 holes in a single operation) to produce acoustic panels for special applications, such as insulating the walls of a jet engine unit.

We manufacture this industrial nail, whose head and body meet the stringent specifications for assembly in large quantities on a sheet positioned on special tooling which perfectly fits the shape of the surface to be pierced and then strikes the nails.

Axfil handles the entire production line, starting with the steel wire, which is straightened, precision cut and shaped at both ends: a precision ogival tip at one end and a head formed by cold heading at the other, with a diameter of ±0.15 mm.

We then use the services of a trusted partner to quench and nickel plate the part to deliver a conditioned end product that meets all of the customer’s requirements.

Materials

Carbon Stainless Steel XC80, quenching + nickel plating

Sector

Aerospace